Ingxelo yabucala: Ubumfihlo bakho bubaluleke kakhulu kuthi. Inkampani yethu ithembisa ukungazivezi iinkcukacha zakho kuye nakuphi na iimvume zakho.

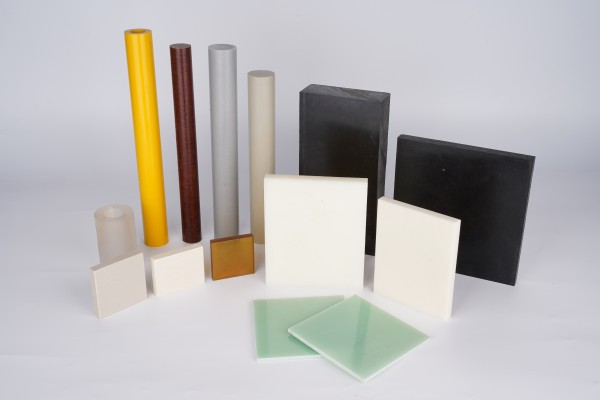

Iplastiki yi-monomer njengezixhobo eziluhlaza, nge-polymerization okanye i-polycondetions yokuphendula ye-Polymer ye-Polymer ye-Polymer ye-Polymer ye-Polymer ephakathi, phakathi kwe-fiber okanye irabha, i-fistles, iziqwengana, ioyile, ioyile, ioyile, ioyile, ioyile, ioyile, ioyile, ioyile, ioyile, ioyile, ioyile Faka umbala kunye nezinye iisongezo.

Eyona nto iphambili yeplastiki i-resin. I-resin yindawo ye-polymer engekadityaniswa neezongezo ezahlukeneyo. Igama elithi Retin ekuqaleni lalibizwa emva kokuba i-lipids igcinwe zizityalo nakwizilwanyana, ezinjengeRosin kunye neMhlosi. I-resin i-akhawunti malunga ne-40% ukuya kwi-100% yobunzima beplastiki. Iipropati ezisisiseko zeplastiki zimiselwa ikakhulu ngohlobo lwe-resin, kodwa iiopanitives zidlala indima ebalulekileyo. Ezinye iiplasitiki zibunjwe yi-Synthitic i-syntitic iqulathe, iqulathe hayi okanye ezimbalwa, ezinjengePlexiglass, njl.

Iplastiki bubugcisa bezinto eziphambili, kubushushu obuthile kunye noxinzelelo lubunjwe lube yimo ethile, kwaye kubushushu begumbi unokugcina ubume obumiselweyo kwizixhobo ze-polymer. Iplastiki kukukhanya kwaye yomelele. Ukuxinana ngokubanzi kwe-0.9-23300G / MM3, yi-1 / 8-1 / 4 yentsimbi ye-ial, i-aluminium 1/2, ukuhanjiswa okuhle kunye nokuhanjiswa okuhle nokukhuseleka Ukuthathwa komzimba kunye nokupheliswa kwesandi. Iiplasitiki ngokwenziwa kokusebenza kobushushu bomphezulu zahlulahlulwe zangamatheko ziya kubanjwa kunye neplastiki ye-thermoplastic.

Iimpawu zeplastiki ezithile: Kumgangatho othile emva kokufudumeza, uxinzelelo okanye ukongeza i-HORDEAL SHICY KUNYE NOKUQHUTYWA KOKUSETYENZISWA KWEXESHA LOKUGQIBELA Iqondo lokushisa liphezulu kakhulu kwi-Deation. Njengobubele obunjenge-feolic (ezixhaswayo njenge-Bokheli), i-Epostoxy Plastics (EP) njalo njalo.

Iimpawu zeRomastic: Utshintsho lobushushu kwimeko yomzimba ngokuqhutywa ngokuqinileyo okanye ukunyibilikisa kwi-vidi fall, kodwa emva kokupholisa kwaye kunokuba nzima, kwaye inkqubo inokuphindaphindwe kaninzi. Isakhiwo se-molecular seplastiki asitshintshi. Njengeplastiki ye-polythyenene (i-PE), iPolyvinyl iplastiki yeplastiki (PVC).

| Ukwahlulahlulahlulahlulahlulahlula | Umxholo | Iiplasitiki | |

| Ukwahlulahlulwa ngesicelo | Iiplasitiki zobunjineli | Ngokubanzi ibhekisa kwinani leeplasitiki zomgangatho wamashishini afana nezo zisetyenziswa ekwenzeni kwamalungu omchwephesha okanye izinto zobunjineli | I-P PC POM ABS PPO PPT |

| Iinjongo ngokubanzi | Izinto zeplastiki ezineempawu ngokubanzi zezinto zeplastiki kwaye azikwazi ukutshintsha izixhobo zeplastiki okanye zeplasitiki | I-pvc ps phenolic, i-amino pript | |

| Ukwahlulahlulwa kwezixhobo zomzimba kunye neekhemikhali | I-thermoplastic | Iiplasitiki ezinokuphinda ziphindwe kabini ukuba zithambekele kwaye zipholile ukuba zikhule kwaye zibunjwe | I-P PC POM ABS PPO PPO PVT PS |

| I-Thermoset Plastics | Iplastiki enyangwe bushushu kwaye yathatyathwa bubushushu kwaye iphinde ibunjwe kwakhona. I-synthetic i-resins enokusetyenziswa kuphela | I-thonolic, i-aminino, i-epoxy kunye ne-resin | |

| Ubume beplastiki | I-inssors, iifilitha, iiplastiki, ezikolo, izilo, ii -olbrients, njl. | ||

| Izizathu ezichaphazela umgangatho weenxalenye zeplastiki | 1.Cefact uyilo lwe-2.PPEistic loyilo kunye nemveliso yokwenziwa kwemveliso ye-3.Machication ye-4.Machine yoLungiso lweMigangatho | ||

| I-paramitha | Ubushushu | a. Iqondo lokushisa le-cylinder b. Ubushushu be-nozzle c. Iqondo lobushushu | |

| Uxinzelelo | a. Uxinzelelo lwe-clpping b. Uxinzelelo lwenzuzo c. Ukubamba uxinzelelo d. Uxinzelelo lwangasemva | ||

| Isantya | a. Isantya sokukhawulezisa b. Isantya sokuvala c. Isantya sesantya d. Isantya sokuvula | ||

| Ixesha | ixesha lokufumana ixesha lokubamba ixesha lexesha lokupholisa | ||

| Izinto ezichaphazela ukuqukuqela kwezinto zeplastiki | 1. Iindidi zeplastiki 2. Isakhiwo soMnyama 3. Inkqubo yokuBulfting 4. I-Hygroscopity, imvakalelo ye-Irmal kunye ne-Irmal Worting kunye ne-Crystaing 6. I-Crystallied 6. Ukutsala isantya |

Esona siphene seemveliso zeplastiki:

1. I-Phi Peak : Ngenxa yeparameters yenaliti okanye imbungu ngokwezizathu zeplastiki, ubukhulu becala kwi-theming right, i-thimble, isilayidi, isilayidi kunye neminye imisebenzi

2. Shrinkage: Xa iplastiki inyibilika kwicandelo elincinci le-rock, ilahleko yoxinzelelo inkulu kakhulu, kunzima ukugcina uxinzelelo oluphezulu lokugcwalisa icandelo lomnqamlezo olwenziweyo kunye nokuqulunqwa kwemingxunya

3. Umgca we-fusion (umgca wamanzi) : Ukunyibilika kweplastiki kwi-cavity xa kuhlanganiswa imiqobo (ekoreyini kunye nezinye izinto) ukuba zingabi nako ukuncipha kweplastiki kumphezulu weplastiki

4. I-Shomoeline : Izinto ezingafunekiyo kwi-mold cavity ihamba phezu kwamanzi njengeziko lemigca yonyaka

5. Ukunqongophala kweglue (i-purfill): Ngenxa yengxwabangxwaba engaphelelanga okanye ukuphazamiseka okungapheliyo kwikona yomngxunya kunye ne-thenomen yendawo engakhange ibanjiswe yiglue

6. I-White White White (i-convex ephezulu): Ngenxa yokukhutshelwa okungalunganga, umphezulu wemveliso uxhomekeke kumandla e-elup kwaye uvelise amanqaku amhlophe okanye amaqhekeza amhlophe

7. IZIBHENGEZO: A Ngenxa yezinto ezingafunekiyo ekubunjweni ngaphambi kokusoma okuphezulu, amanzi kubushushu obuphakathi kwe-china kunye nokusekwa kweebhubhu ze-BUROR kwimveliso ephezulu Kwinqanaba lokupholisa kunendawo yeziko lokukhawulezisa ngokuqina, embindini wexesha lokwahlulahlula i-resin, ukuze inxenye yenxalenye yokuzaliswa kwe-vabuum yeva

8. Ukutyibilika

9. ISISHWANKATHELO: Imveliso ebunjiweyo ngenxa yezizathu ezithile zoxinzelelo lwangaphakathi lwentsalela emva kokudilizwa kwengxaki yesiphumo

10. I-crocks: Ngenxa yoxinzelelo lwangaphakathi okanye ukonakaliswa koomatshini okubangelwe zii-rocks okanye imingxunya encinci kwimveliso, ikakhulu ngenxa yoxinzelelo lwentsalela, uxinzelelo lwangaphandle okanye uxinzelelo lwendalo

11. Tsala i-White: Iimveliso ezibumbayo kwi-mold ngenxa yengxwabangxwaba ye-HOOP inkulu kunamafutha aphezulu kwe-piesting, ukuze amanye amalungu emveliso emhlophe

12.ntyatyambo

13. Umahluko wemibala: Umphezulu wemveliso awungqinelani nomfanekiso oqhelekileyo wesampulu

November 14, 2024

November 13, 2024

October 20, 2022

October 20, 2022

I-imeyili kule mthengisi

November 14, 2024

November 13, 2024

October 20, 2022

October 20, 2022

Ingxelo yabucala: Ubumfihlo bakho bubaluleke kakhulu kuthi. Inkampani yethu ithembisa ukungazivezi iinkcukacha zakho kuye nakuphi na iimvume zakho.

Gcwalisa ulwazi oluthe kratya ukuze unxibelelane nawe ngokukhawuleza

Ingxelo yabucala: Ubumfihlo bakho bubaluleke kakhulu kuthi. Inkampani yethu ithembisa ukungazivezi iinkcukacha zakho kuye nakuphi na iimvume zakho.