Ingxelo yabucala: Ubumfihlo bakho bubaluleke kakhulu kuthi. Inkampani yethu ithembisa ukungazivezi iinkcukacha zakho kuye nakuphi na iimvume zakho.

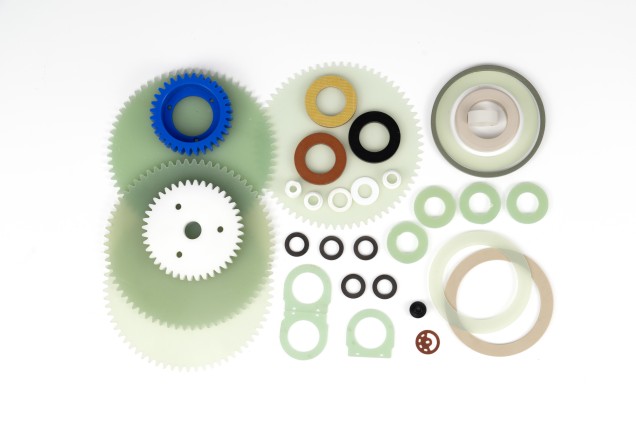

Ukulungiswa kwebhodi ye-Epoxy kunye nokulungisa ezinye iipaneli zokufakwa ezifanayo ziyafana: Ukujika, ukugaya, ukusika, ukuqhuba, ukugaya, ukugaya, ukugaya, ukugaya. Inkqubo yokuqhubekeka kwebhodi ye-Epoxy kunye nokusetyenziswa kwezixhobo ezahlukeneyo zokulungisa.

Kwinkqubo yokuqhubela phambili kwe-EPOXY kufuneka inikele ingqalelo kule nkcukacha:

1. Inkqubo yokuqhubekisa iya kuvelisa iitshipsi ezicocekileyo kunye neengxaki zokupholisa, okhoyo ukubetha komoya ocociweyo uhlengahlengiso oluncinci, ukubetha nje i-chips yomnxeba emgceni.

2. Ukulungiswa kweplate ye-Epoxy kuya kuvelisa uthuli oluninzi, unokukhetha ukusebenza ngamanzi, ukukhetha i-vacuum yenkqubo yokuhombisa i-Decoum.

3. Inkqubo yokulungisa, kuya kubakho iqondo eliphakamileyo kakhulu. Kuya kufuneka silawule ubushushu ngexesha elifanelekileyo. Izinto ezisisiseko zebhodi ye-Epoxy yi-Epoxy Rin Glue, kunye nendawo yokunyibilika ye-Eposn Gein Glues malunga ne-155 degrees malunga ne-155 degrees malunga ne-155 degrees malunga ne-155 degrees. Ngaphezulu kobushushu, iBhodi iya kuvela into ethambileyo.

4. Khetha iBhodi ye-EPOXY elungileyo, ukuba imfuneko yoxinzelelo ayiphezulu, unokukhetha iBhodi ye-Epoxy ye-Eposm. Isetyenziselwa ukuntywila ngokubanzi isebenza. Ukuba imfuno yevolthi iphezulu kakhulu, unokukhetha iBhodi ye-Eposm e-Eposmy.

Ukuthatha amanyathelo ngexesha lokuqhubekeka kweepleyiti ze-Epoxy

Iphepha le-Epoxy yinto esetyenziswayo yeplastiki esetyenzisiweyo yeplasitiki eneemeyile ezigqwesileyo, iipropathi zombane kunye neekhemikhali. Ngexesha lokuqhubekeka kwephepha le-EPOXY, kufuneka kuqatshelwe le micimbi ilandelayo ukuqinisekisa ukuba umgangatho wokwenza umgangatho kunye nokhuseleko lokusebenza.

1. Khetha inkqubo efanelekileyo yokulungisa: ngokweenjongo zokulungisa ezinqwenelekayo kunye neemfuno, khetha inkqubo efanelekileyo yokulungisa, njengokusika, ukuqhuba, ukugaya, njl .. kufuneka ukhethe ngokwemeko yokwenyani.

2. Gcina imeko elungileyo yokusebenza: Kubaluleke kakhulu ukugcina imeko elungileyo yokusebenza ngexesha lokusebenza. Qinisekisa ukuba indawo yokusebenza ingena umoya kwaye kude kakhulu ukuba ivule, kuqhushumbe kunye nezinye izinto eziyingozi. Kwangelo xesha, abaqhubi kufuneka banxibe izixhobo ezifanelekileyo zokhuselo, ezinjengeegloves, iigogo, njl njl, ukukhusela ukhuseleko lwazo.

3. Sebenzisa izixhobo ezifanelekileyo zokwenza: Ukukhetha izixhobo ezifanelekileyo zokulungisa sisitshixo sokuqinisekisa umgangatho wokuqhubekeka. Sebenzisa umgangatho othembekileyo, ofanelekileyo kwizixhobo ezisebenzayo, ezinje ngezantya eziphakamileyo zezantya, zibone iivili, zokugaya, njalo njalo. Nikela ingqalelo ukugcina ubukhali bezixhobo, kwaye zihlole rhoqo kwaye zibuyise izixhobo ezonakeleyo okanye ezimbi.

4. Lawula iqondo lobushushu: kwinkqubo yokulungisa, ukulawula ubushushu benkqubo kubaluleke kakhulu. Iqondo lokushisa eligqithileyo linokubangela ukuba izinto zinyibilike, zisebenze okanye ziphendule iipilisi, oko kuchaphazela umgangatho woomatshini. Ke ngoko, kuyimfuneko ukulawula ubushushu obufanelekileyo bokwenza izinto kwaye uthathe amanyathelo afanelekileyo okupholisa ngexesha lenkqubo yomatshini ukuqinisekisa uzinzo kunye nomgangatho wenkqubo yomatshini.

5. Thintela ukuveliswa kombane oqingqiweyo: Iibhodi ze-EPOXY zithambekele kumbane oqingqiweyo, ukuqokelelwa kombane oqingqiweyo kunokubangela ukuphazamiseka ekusekweni okanye ukonakala kwimiba. Ke ngoko, kwinkqubo yokusebenza, amanyathelo alinganayo ahambelana nayo kufuneka athathwe, njengokusetyenziswa kwezixhobo ezinezixhobo ze-anti-static, nxiba iimpahla ezichasene ne-anti-static, njl njl.

6. Ukucocwa rhoqo kunye nokugcinwa kwezixhobo: Ukucocwa rhoqo kunye nokugcinwa kwezixhobo zenkqubo yeyona nto iphambili ekuqinisekiseni umgangatho wokufezekiswa kunye nezixhobo zobomi. Coca iitshipsi kunye nobumdaka kwizixhobo zokugcina izixhobo zikwimeko elungileyo. Kwangelo xesha, jonga rhoqo kwaye ugcine izinto ezahlukeneyo zezixhobo, ezinje ngenkqubo ye-wibridation, isixhobo sokuhambisa, njl., Ukuqinisekisa ukusebenza kwayo kwesiqhelo kunye nokusetyenziswa okukhuselekileyo.

7. Landela iingcebiso zababoneleli: Abathengisi abahlukeneyo banokubonelela ngeendululo ezahlukeneyo zokulungisa kunye neeparamitha. Ngexesha lokuqhutywa, iiparamitha ezilungisa zilungiswe ngokufanelekileyo ngokweempawu zezinto ezithile kunye neengcebiso zomthengisi, kwaye iinkonzo zobugcisa boMthengisi kunye neenkonzo zokubonisana kufuneka zisetyenziswe ngokupheleleyo.

Ukushwankathela, xa kuqinisekiswa ukukhetha itekhnoloji yokuqhubela phambili, ugcina indawo efanelekileyo yokusebenza, usebenzisa ubushushu obusebenzayo, ukulawula umbane wombane, ukucoca rhoqo kunye nokulungiswa kwezixhobo, kwaye ulandele Iingcebiso zomthengisi. Ngokujonga ezi ndlela zokuthatha amanyathelo okhuseleko, umgangatho kunye nokusebenza kakuhle kwenkqubo ye-EPOXY kungaphuculwa ngelixa uqinisekisa ukhuseleko lwabasebenzi.

November 14, 2024

November 13, 2024

October 20, 2022

October 20, 2022

I-imeyili kule mthengisi

November 14, 2024

November 13, 2024

October 20, 2022

October 20, 2022

Ingxelo yabucala: Ubumfihlo bakho bubaluleke kakhulu kuthi. Inkampani yethu ithembisa ukungazivezi iinkcukacha zakho kuye nakuphi na iimvume zakho.

Gcwalisa ulwazi oluthe kratya ukuze unxibelelane nawe ngokukhawuleza

Ingxelo yabucala: Ubumfihlo bakho bubaluleke kakhulu kuthi. Inkampani yethu ithembisa ukungazivezi iinkcukacha zakho kuye nakuphi na iimvume zakho.