Ingxelo yabucala: Ubumfihlo bakho bubaluleke kakhulu kuthi. Inkampani yethu ithembisa ukungazivezi iinkcukacha zakho kuye nakuphi na iimvume zakho.

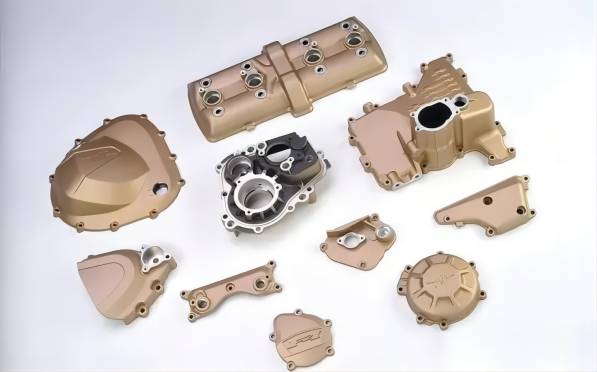

Ixabiso le-sunk lomatshini we-CNC onokuthi aphezulu kunezo zendlela zemveli. Nangona kunjalo, ekuhambeni kwexesha, izibonelelo ezinikezelwe yinkqubo ngokuqinisekileyo zenza ukuba ixabiseke kutyalo mali olongezelelweyo. Namhlanje ndiza kwabelana nawe ngezibonelelo zomatshini we-CNC.

1. Ukudilizwa ngokungqongqo

Ukuqina okuqinileyo sesona sizathu siphambili sokusebenzisa indlela ye-CNC. Umntu unokubuza: Yintoni ukunganyamezeli?

Umahluko, oko kukuthi, impazamo, into esiyenzayo isenokungafani nobukhulu obuqingqiweyo, kunokubakho impazamo, kodwa lo gama nje isekhona ngexesha lodidi olwamkelekileyo, emva koko le nto isasetyenziswa. Kunye nokunyamezelana kukwabizwa ngokuba kukuchaneka kokuchaneka. Ibhekisa ekuphanzisweni kancinci kubungakanani benxalenye yenxalenye ye-CAD ye-CAD. Indlela yokuchaneka kwe-CNC isebenzisa iinkqubo ezizodwa kunye nezixhobo zokusika ukunciphisa ukungangqinelani kweyona milinganiselo incinci. Oku kukhokelela ekuchanekeni okukhulu kwenxalenye ethelekiswa ne-blowrint yoqobo.

Umatshini wokuchaneka ngokwenziwa ngeyona ntlobo zine ezahlukeneyo zokuqina koomatshini:

Ukunyamezelana kwendlela enye: kolu hlobo lokunyamezelana, umahluko omkhulu uvunyelwe kwicala elinye. Imida yokunyamezelana inokuphezulu okanye iphantsi kunemilinganiselo elindelweyo.

Ukunyamezelana kwe-Bilatatal: Kolu hlobo lokunyamezelana, ukwahlukahlukana komgangatho kuvunyelwe kuzo zombini iindlela. Ukunganyamezelwa kwemida engaphezulu okanye ngaphantsi kwemilinganiselo elindelweyo yamkelekile.

Ukunyamezelana okuyintloko: Ukunyamezelana kwengqumbo yifolokhwe yokugqibela ebalwe ngokudibanisa okanye ukukhupha ubume bemilinganiselo eyahlukeneyo eyenza le nxalenye.

Ubungakanani bomda: Chaza ubungakanani bomda ophezulu kunye nophantsi endaweni yesayizi enqwenelekayo. Umzekelo, ubukhulu besenzi bunokuba luluhlu lwe-20mm ukuya kwi-22mm.

2. Ukuchaneka okuphezulu

Iifolda eziqinileyo zibonisa ukuba imveliso yokugqibela eyenziwe ngomatshini ochanekileyo iya kuba nokuchaneka okukhulu. Umatshini wokuchaneka uqhubeke ngokubanzi kwiindawo ezifuna ukusebenzisana namanye amalungu. Ke ngoko, ukuchaneka okuphezulu kubalulekile kula macandelo athile ukuba asebenze ngokugqibeleleyo kwisithuba eso.

3. Ukuphindaphinda okuphezulu

Umbono wokuphindaphindiso yenye yeendawo eziphambili zemveliso yanamhlanje. Zonke inxalenye eyenziweyo yinkqubo ijongeka ifana nelinye icandelo kumsebenzisi wokugqibela. Nakuphi na ukuphambuka kokuzala kwathatyathwa sisiphene. Indlela yokuchanekayo inomdla kule meko. Sebenzisa i-CNC efanelekileyo ye-CNC, icandelo ngalinye linokwenziwa ngokuchanekileyo njengoko kwasekuqaleni, kwaye ukuphambuka kuncinci kangangokuba kungakhathalelwa.

4. Ixabiso lemveliso eliphantsi

Kuba akukho kuphambuka kuMatshini ochanekileyo, iimveliso ezimbalwa ezinesiphene ziveliswa. Ke ngoko, le nkqubo inokunciphisa kakhulu inqanaba le-scrap amalungu. Ke ngoko, iindleko ezibonakalayo ziphantsi. Ukongeza, iinkqubo zokwenza iimoto ezisebenza ngekhompyuter zinokunciphisa iindleko zabasebenzi. Ukuncitshiswa okudityanisiweyo kwezabasebenzi kunye neendleko zezinto ezibonakalayo kuthetha ukuba iindleko zokuvelisa zinomatshini we-CNC ziphantsi kunenye indlela.

5. Isantya kunye nokusebenza kakuhle

Umatshini wokuchaneka kubandakanya iirobhothi ezihamba ngesantya esiphezulu ezinokwenza iinxalenye zenziwe ngokukhawuleza kunokuvelisa i-leathes. Ukongeza, la macandelo agqityiwe ngokuchaneka okuphezulu kunye nokuqina okuqinileyo, ngoko akukho machiza anesibini kuyafuneka. Oku kunciphisa ixesha lemveliso kwaye kunyusa ukuvelisa kunye nokusebenza kakuhle kumgangatho wevenkile.

6. Izakhono zokusebenza ezintsonkothileyo

Izixhobo ze-CNC zinokwenza imisebenzi entsonkothileyo enjengokuthi i-3d Milling engaphezulu, icofa izandla, kunye ne-axi-axi-axi-axine ngendlela efanayo. Banokulawula ngokulandelelana ukuhamba kwezixhobo kunye neendlela zomsebenzi ngokweenkqubo ezibhaliweyo zangaphambi, zivumele ukulungiswa kweemilo ezintsonkothileyo kunye nezakhiwo.

7.batha-

Izixhobo ze-CNC zoomatshini zithathe indawo yokusebenza kwamanani ekhompyuter kwaye ishenxise into yomngcipheko kwimpazamo yomntu ebandakanyeke kwinkqubo yokusika, ukunciphisa ingozi kubasebenzi abanokubakho xa besebenzisa izixhobo zomatshini. Abasebenzi baye bakwazi ukufudukela kwizikhundla ezinobuchule, ezinje ngemisebenzi yoyilo ye-CNC.

8. Ukunciphisa impazamo yomntu

Kuba ukusebenza kwezixhobo ze-CNC zoomatshini kulawulwa ziikhompyuter, ifuthe lezinto zabantu ekuqhubeni kuncitshisiwe. Iimpazamo zabantu, ezinjengokudinwa, ukusebenza okungahambelaniyo kunye nomgwebo, zihlala zikhokelela kwiziphumo ezimbi zoomatshini. Sebenzisa izixhobo ze-CNC kunokunciphisa ezi mpazamo kwaye kuphuculwe ukungqinelana kunye nokuchaneka komatshini.

Amanqaku ayi-8 angentla malunga nezibonelelo aziswe ngumatshini we-CNC. Emva kokufunda oku, wonke umntu kufuneka abe nokuqonda okucacileyo.

November 14, 2024

November 13, 2024

October 20, 2022

October 20, 2022

I-imeyili kule mthengisi

November 14, 2024

November 13, 2024

October 20, 2022

October 20, 2022

Ingxelo yabucala: Ubumfihlo bakho bubaluleke kakhulu kuthi. Inkampani yethu ithembisa ukungazivezi iinkcukacha zakho kuye nakuphi na iimvume zakho.

Gcwalisa ulwazi oluthe kratya ukuze unxibelelane nawe ngokukhawuleza

Ingxelo yabucala: Ubumfihlo bakho bubaluleke kakhulu kuthi. Inkampani yethu ithembisa ukungazivezi iinkcukacha zakho kuye nakuphi na iimvume zakho.